The Challenge

Unsustained results after project finishes

Unstructured Approach to Communicate Project Results

Problem

• Difficulty in sustaining implemented improvements, once projects have been completed

• Similar improvement projects being implemented simultaneously

• Improvement initiatives not perceived as part of daily activities by team leaders

Root Causes

• Loss of momentum when improvements are passed on to Gemba management

• Lack of overall visibility over ongoing projects and guarantee of alignment with company vision

• Poor improvement routines in the daily agendas of team leaders and disconnection between improvement culture and performance evaluation

The solution

From Strategy to System CIP

Process Confirmation

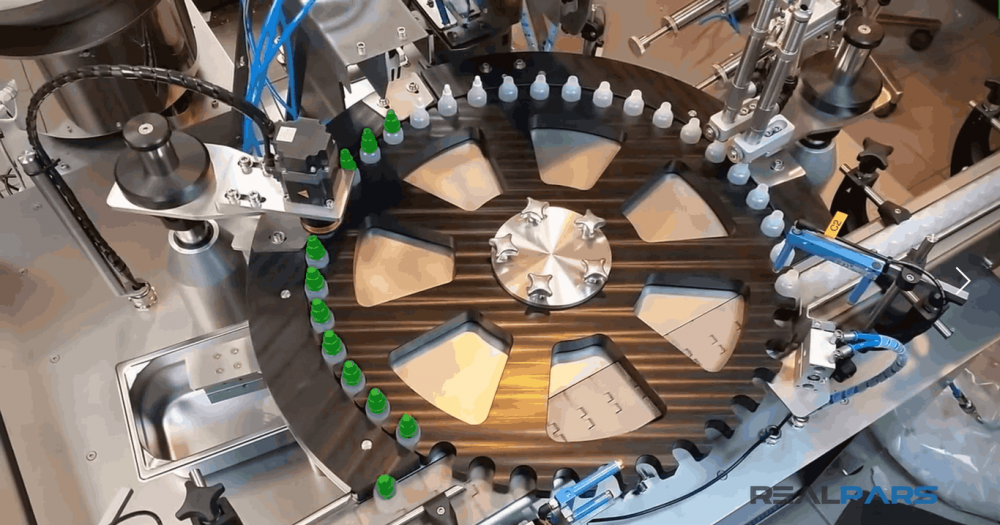

• Continuous Improvement Process (CIP) is composed of two levels: System CIP – holistic approach to improve the whole value stream with disruptive changes; and Point CIP – focus on the workplace or line to stabilise and improve existing standards

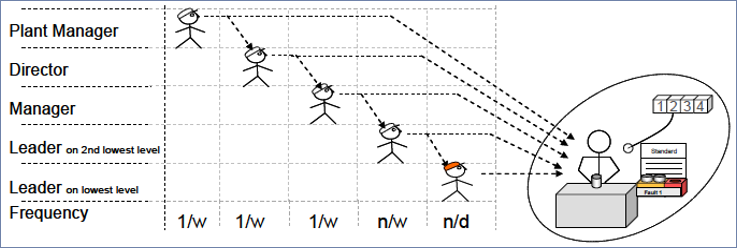

• Daily Management is ultimately responsible for sustaining the results after Point CIP has eliminated the largest causes of variability through standards and process confirmation, quick reaction systems and structured communication

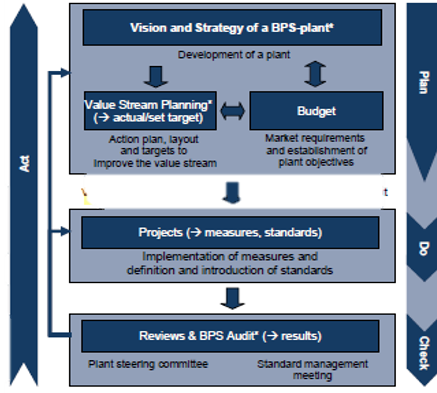

• Initiatives implemented with System CIP are deployed from Vision and Strategy along with Value Stream Analysis and, once closed, are Reviewed and Audited

The Results

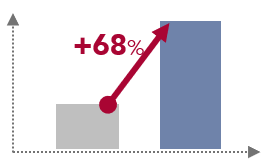

Productivity (parts/hour)

Productivity of labour increased by 68%.

First Time Through

First time quality increased by 20%.

OEE

Overall equipment efficiency of plant increased by 18%.

#assembly manufacturing #culture and organisation #improvement projects

See more on Assembly Manufacturing

Find out more about transformation in this sector

See more on Culture & Organisation

Find out more about improving this business area