The Challenge

Poor workplace organisation

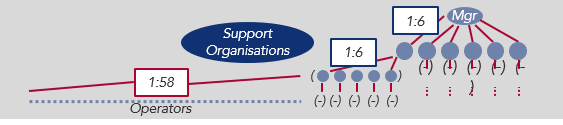

Incorrect team dimensions

Problem

• Lack of management by objectives (KPIs)

• Lack of organisation of physical spaces, which limits productivity

• Difficulty in standardising knowledge in Teams and effectively training new employees

Root Causes

• Teams without autonomy in process maintenance and improvement

• Lack of proactivity in process improvement

• Weak culture of continuous improvement and lack of routines

• Suboptimal number of team members in each team, contributing to poor coordination of teamwork

The solution

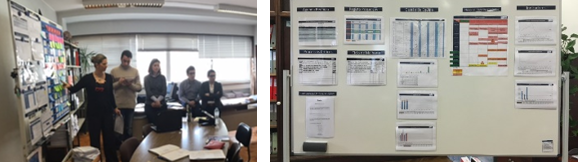

Team meetings with visual management

Workplace organisation

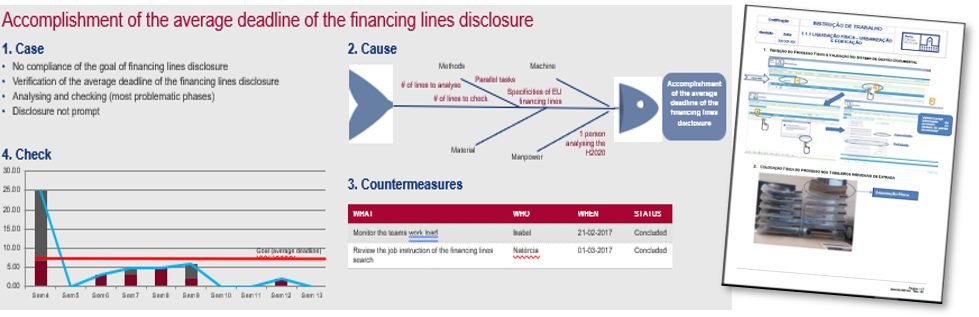

Standardisation and Structured Problem Solving

• Daily Team Meetings: supported by team boards with KPIs, Work Plan, Definition of Priorities and Improvement Cycle

• Digital and Physical workplace organisation to boost productivity, improve process transparency and create a better working environment

• Office Standard Work and Structured problem solving to improve process efficiency and automate procedures, facilitating employee training – over 100 tasks standardised

• Team Development Programme to roll out implementation to all areas

The Results

The daily improvements of the teams generated annual savings of £400,000 per year.

Errors

The number of process errors decreased by 30%.

Team Versatility

Team polyvalence increased by 40%.

Average Execution Time

Task execution times decreased by 60%.

#public sector #daily management

See more on Public Sector

Find out more about transformation in this sector

See more on Culture & Organisation

Find out more about improving this business area